First things first. It is important to understand that 'lots of

data' and 'big data' are different!

Traditional technology has been

serving organizations’ analytics needs for decades, allowing them to analyze

large data sets from traditional sources such as warehousing and distribution

systems.

‘Big data’ takes it to the next level, allowing companies to harness extremely large data volumes including non-traditional data types such as text, audio and video in conjunction with information from business systems in a much more economical fashion, in both batch and in real time modes. While the sheer volume of data available to a company today is daunting, the first step in leveraging 'big data' is deciding on the problem you want solved, or the issues you need addressed, and then finding the proper data necessary. It is more than just 'look-back information', of say how many containers or TEUs you shipped in May 2016 from Chennai/Mumbai to Rotterdam, but rather pulling the data necessary to ship them cheaper, faster, or to achieve whatever metric you need addressed.

‘Big data’ takes it to the next level, allowing companies to harness extremely large data volumes including non-traditional data types such as text, audio and video in conjunction with information from business systems in a much more economical fashion, in both batch and in real time modes. While the sheer volume of data available to a company today is daunting, the first step in leveraging 'big data' is deciding on the problem you want solved, or the issues you need addressed, and then finding the proper data necessary. It is more than just 'look-back information', of say how many containers or TEUs you shipped in May 2016 from Chennai/Mumbai to Rotterdam, but rather pulling the data necessary to ship them cheaper, faster, or to achieve whatever metric you need addressed.

Is Big Data just another expensive IT solution then?

No; Big data is not about IT at

all; remember the term “Garbage In = Garbage Out? That is applicable for too-much data, and not for Big

Data.

A company needs to determine what they want to do

Does the company want to reduce GHG emissions?

Does the company want to reduce costs? OR Increase revenue?

Does the company want to Optimize transit times?

These are all serious strategic issues for both a carrier and a shipper, whose implementation – or not – affects profitability on every voyage. The carrier needs to sit with the Consultants / IT firms to figure out the questions that need to be asked in order affect positive outcomes, and determine what is the traditional and non-traditional data that goes into profitability.

A company needs to determine what they want to do

Does the company want to reduce GHG emissions?

Does the company want to reduce costs? OR Increase revenue?

Does the company want to Optimize transit times?

These are all serious strategic issues for both a carrier and a shipper, whose implementation – or not – affects profitability on every voyage. The carrier needs to sit with the Consultants / IT firms to figure out the questions that need to be asked in order affect positive outcomes, and determine what is the traditional and non-traditional data that goes into profitability.

What is traditional data vs. non-traditional data?

Traditional data is look-back

data from ordinary business systems; fuel costs, transit times, wages,

insurance, revenue per TEU. It's accounting data that's used to determine the

profitability of a voyage.

Non-traditional data is time-sensitive data – weather and traffic delays, port strikes, unexpected repairs. It’s also extremely large volumes of data being generated from sensors, GPS devices, RFID tags and traffic management systems. If Big Data can assist in helping forecast or avoid problems, the money saved goes straight to profitability

Non-traditional data is time-sensitive data – weather and traffic delays, port strikes, unexpected repairs. It’s also extremely large volumes of data being generated from sensors, GPS devices, RFID tags and traffic management systems. If Big Data can assist in helping forecast or avoid problems, the money saved goes straight to profitability

Is non-traditional data quantifiable?

Some of the non-traditional data

is quantifiable, some isn't, but it's all related to issues that can be

resolved or avoided.

For example, If a storm blows up, would you steam through it? Perhaps not, but you would use a ‘big data’ solution to analyze GPS-type information to quickly determine the costs of other routes as opposed to not diverting. Or a 3PL might get a message from his GPS about a highway being closed, so instead of having the truck idling in traffic burning fuel and time; the driver would be re-routed.

Preventive technology is a lifesaver for most forms of transportation from a container ship to a delivery truck; modern sensor technology enables the carrier to be warned of failures before they occur, which allows management to affect repairs prior and on a timely basis, instead of being stuck in port on demurrage or being towed off the motorway. Sensor information can be leveraged to predict a failure rather than waiting for it to occur.

For example, If a storm blows up, would you steam through it? Perhaps not, but you would use a ‘big data’ solution to analyze GPS-type information to quickly determine the costs of other routes as opposed to not diverting. Or a 3PL might get a message from his GPS about a highway being closed, so instead of having the truck idling in traffic burning fuel and time; the driver would be re-routed.

Preventive technology is a lifesaver for most forms of transportation from a container ship to a delivery truck; modern sensor technology enables the carrier to be warned of failures before they occur, which allows management to affect repairs prior and on a timely basis, instead of being stuck in port on demurrage or being towed off the motorway. Sensor information can be leveraged to predict a failure rather than waiting for it to occur.

This sort of information would be equally important for the shipper?

Yes; whether you are

shipping the goods as a vendor, or receiving them as the buyer; getting them to

the final destination on time, undamaged, and in a cost-effective manner is

important. Whether the data comes from the carrier, or is transmitted via RFID;

it's data the shipper can use to quantify his shipping metrics and work on

improvement.

Is there a place for Big Data in Supply Chain Management?

Yes; in fact it is what

makes advanced SCM possible. It is using Big Data to start replacement inventory

moving before inventory is exhausted; it's taking look-back vendor reliability

data and instead of just disqualifying those who missed shipments, rewarding

those with good reliability as well as others who stepped up to cover for those

vendors who failed. It’s bringing information together from multiple sources to

make predictions and real-time decisions to keep the logistics pipeline

flowing. Remember, Big Data is used to quantify what you, the customer, has

determined is important to your business.

Consultants / IT firms with

required industry business and technical expertise can make sense of the ‘big

data’ and provide strategic direction and answer business-critical questions

based on the facts coming from the data

Success Stories: NYK & K Line achieve CO2 Emissions by Using Big Data

Japanese shipping companies NYK

Line and Kawasaki Kisen Kaisha (K Line) achieved CO2 emission cuts from their

ships in 2015 by using energy-saving technologies, primarily big data, and they

are setting further targets to cap the emissions.

NYK line reduced its CO2

footprint by 14.3 percent, exceeding its goal established in 2011 – reduction

of ten percent by 2015 in the CO2 emission rate per unit of transportation from

vessels compared with the rate recorded in 2010. NYK said it was using its ship

information management system (SIMS) on vessels in 2008, before the

International Maritime Organization (IMO) tightened regulations on CO2

emissions, and currently utilized big data to reduce fuel consumption. The company said it is still

making efforts to attain the next goal – a 15-percent improvement in fuel

efficiency above the 2010 level by 2018.

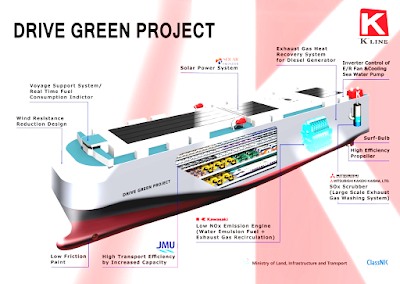

K Line has also announced that it slashed CO2 emissions by 13.6 percent in 2015 against its 2011 level, as a result of deployment of larger vessels, introducing energy-saving technologies and using big data as well.

|

| Big Data has been utilized by K Line to reduce Green House Gas emissions |

K Line has also announced that it slashed CO2 emissions by 13.6 percent in 2015 against its 2011 level, as a result of deployment of larger vessels, introducing energy-saving technologies and using big data as well.

K Line said it accomplished ahead

of schedule the CO2 emission reduction target by ten percent for 2019 against

2011 level. In light of this achievement, the company is to set a new emission

reduction target – 25 percent by 2030. This is part of its vision for 2050 – to

reduce CO2 footprint by 50 percent.

Few & final thoughts on the use of Big Data for shippers and carriers

It is important to remember that Big Data is used in assisting a company in achieving it's business objectives, whether reducing costs or improving efficiency, which is of obvious daily importance to carriers and shippers, or increasing sales, which is of interest to everyone. When properly used, Big Data will enable management to take a gut-feel decisions and quantify it, which lets them take that good idea and make it work.

Few & final thoughts on the use of Big Data for shippers and carriers

It is important to remember that Big Data is used in assisting a company in achieving it's business objectives, whether reducing costs or improving efficiency, which is of obvious daily importance to carriers and shippers, or increasing sales, which is of interest to everyone. When properly used, Big Data will enable management to take a gut-feel decisions and quantify it, which lets them take that good idea and make it work.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.